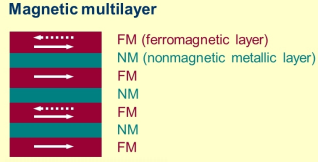

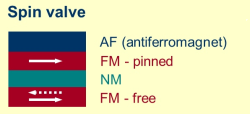

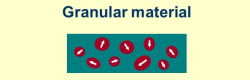

GMR is observed in magnetic metallic layered structures in which it is possible to reorient the magnetic moments of the ferromagnetic layers relative to one another. These structures include magnetic multilayers, spin valves, pseudo spin valves, and granular solids.

In magnetic multilayers this can be achieved due to antiferromagnetic interlayer coupling. The interlayer exchange coupling is mediated by the itinerant electrons in the metallic spacer layer and oscillates between ferromagnetic and antiferromagnetic as a function of the thickness of the nonmagnetic layer. By choosing an appropriate thickness of the spacer layer it is, therefore, possible to create an antiparallel configuration of the ferromagnetic layers and then reorient (align) the moments by an applied magnetic field.

In a pseudo spin valve the antiparallel alignment can be obtained due to different coercivities of the two ferromagnetic layers. The magnetic moments of the soft and hard magnetic layers switch at different values of the applied magnetic field providing a field range in which they are antiparallel and the resistance is higher.

In a spin valve the magnetization of one ferromagnetic layer is pinned by the exchange coupling with an adjacent antiferromagnetic layer, whereas the magnetization of the other ferromagnetic layer is free to rotate with the applied magnetic field. Although the measured values of GMR are higher in magnetic multilayers, spin valves are more attractive from the point of view of applications, because only small magnetic fields need to be applied to change the resistance.

Magnetic granular solids represent another system, which displays the GMR effect. In these materials ferromagnetic precipitates are embedded in a non-magnetic host metal film. The randomly-oriented magnetic moments of the precipitates can be aligned by the applied magnetic field which results in a resistance drop.